DTF printing is a new way to print and brighten up your product. Its fame has spread across sectors. Clothes, homeware, even accessories, they all use it! Why? Custom, imaginative styling is driving demand.

DTF printing (direct to film-) secures the top spot for vibrant, long-lasting prints. Here's a simple guide to DTF transfer technology. It covers the basics, where it's used and the printing process—an ideal starting point for beginners.

Understanding DTF Technology

DTF printing is a method where a design gets printed on a specific film and then to a piece of desired area. It presses on different surfaces with the help of heat and pressure. Renowned for making bright, specific prints, it is immune to heat, dampness, and sunlight. The process works well on many materials like polyester and cotton, and other surfaces. That makes it adaptable and fitting for a variety of uses.

DTF in Different Industries

Different industries have embraced custom DTF printing because of flexibility and high quality. Below are some sectors that can use the method. Even as a small business, you can use the DTf printing method to personalize your products and add value.

Home Decor

DTF printing in home textiles can be an opportunity to customize and tone the fabrics. The plus point is that it is budget-friendly and can be changed whenever you need to add extra decor to your room.

Clothing

Another common industry is clothing, which uses printing almost every day. You can create your own vibrant, enduring designs on any piece of clothing.

Accessories

Another sector is accessories like bags where you can print your personalized designs. You can also start setting up your small tote bags or anything similar. The ease of printing has made it possible for people to add their ideas.

Promotional Products

You can also get products printed for your event or other promotional products. This is one of the most effective methods for small campaigns or corporate gifting.

DTF Printing Process

The DTF Printing process is simple. Below are some basic steps you can follow to make your designs stand out:

- Preparation: Make a design you intend to print on your specific product. Ensure it's high quality, and the colours are not blurred or low pixel.

- Transfer: Film transfer is the second step, where you print your design on a unique film sheet. The film gets reused to transfer.

- Application: In the third step, a special adhesive powder is placed to make a smooth printed film. The powder ensures the ink sticks to the material during the heat press process.

- Heat Press Transfer: Now, it’s time to set your film in the area where you want it to be printed. The heat pressure changes the ink into a liquid fused into the material.

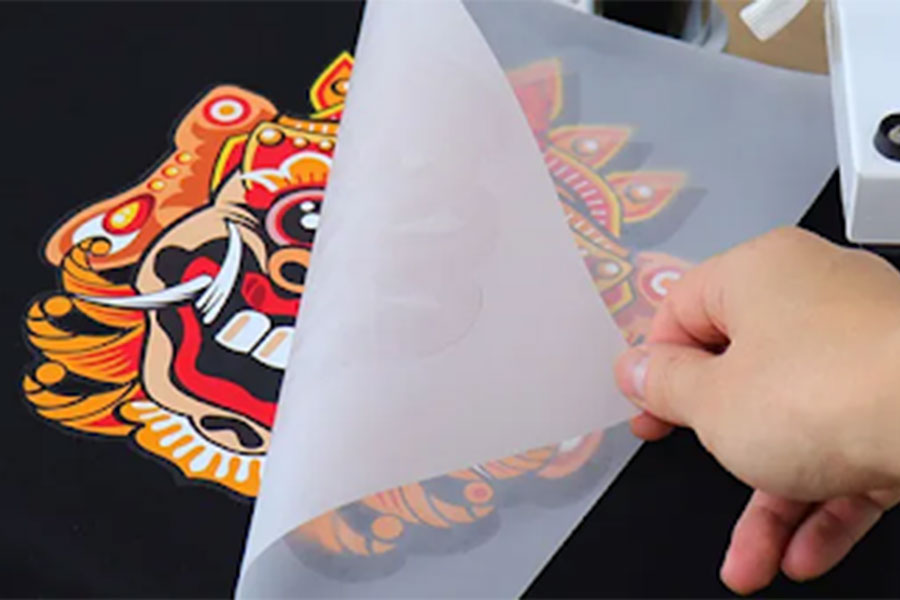

- Cooling and Peeling: Let the material cool down. After the cooling process, you need to peel the film. It might seem easy, but it is a tricky process. Do this step with concentration to keep the design intact.

Critical Considerations for DTF Printing

For best results you need to focus on the following factors:

Heat Settings

Heat temperature matters when transferring the image to the desired product. If the temperature is low, the ink might not transfer. So, if the amount is high, it could damage or spread the material. The process requires help from an expert like Goat Transfers.

Press Time

Another factor is the duration of the heat press. Proper time in the process ensures proper ink transfer without damage.

Trial Runs

The third factor is the trial run. It helps determine the optimal temperature, time, and pressure setting.

Quality Control

Check the prints for clarity and accuracy before moving with production.

Conclusion

Goat Transfer transforms the way designers create and produce designs. It offers Unmatched versatility, quality and durability. It understands the DTF transfer process and key factors.